Steelo Fabrica is a well-known supplier, dealer, and stockholder of SAE-4340 Round Bar and Rod. Our company is engaged in manufacturing the highest quality products like SAE-4340 Round Bar and Rod. We manufacture these round bars according to national and international standards. Our products are highly recommended by our clients due to their long service life and sturdy construction.

Table of Content

Why is SAE 4340 alloy used?

SAE-4340 steel alloy contains chemical elements, which are carbon, manganese, phosphorous, sulfur, silicon, nickel, chromium, and molybdenum. This alloy is known for its toughness and its ability to attain high strength in heat treated conditions. It also shows resistance to fatigue. SAE-4340 alloy contains a slightly higher carbon content. Due to carbon content, this alloy offers better rigidity and provides the capability to heat treatment. It has high weldability characteristics. This alloy steel has good pliable and formability in the annealed condition. It can be twisted or formed by pressing or turning over in the annealed condition. This alloy was welded using the resistance welding method.

What is the SAE-4340 Round Bar?

SAE-4340 Round bars contain medium carbon, chromium, and molybdenum alloy with the addition of vanadium alloy for better hardening. Due to chemical composition, these round bars are able to work in severe conditions. These round bars also show high strength in severe conditions. Our Round bars are one of the best round bars because it’s durable and leak proof properties.

Mechanical properties of SAE-4340 Round bars and rods:

Our company offers these round bars, and rods show good mechanical properties like

• Tensile Strength

• Yield Strength,

• Elastic Modulus

• Elongation at break Hardness.

Our round bars and rods also show physical and thermal properties like low density and high melting point, thermal conductivity, and thermal coefficient of thermal expansion.

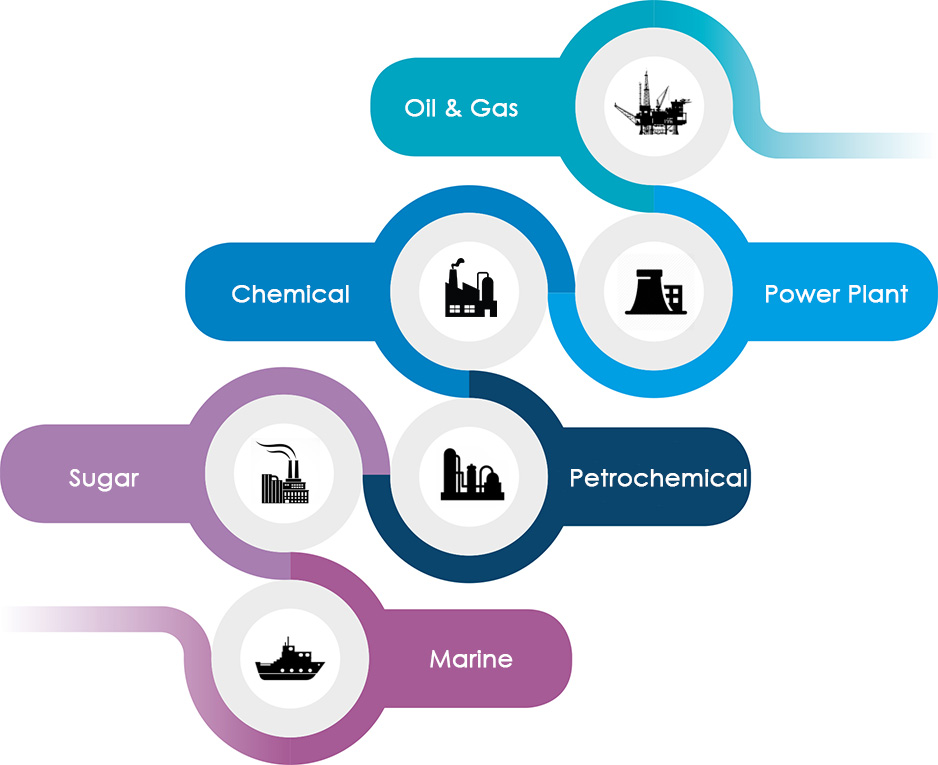

Applications of SAE-4340 Round Bar and Rod:

• Automotive

• Oil and Gas Drilling

• General Engineering Industry and structural use applications like gears, heavy duty shafts.

Specification : ASTM A29, ASME SA29

Grade: 4340

Specification : Alloy Steel 4340 Bar

Square bar size : 4 to 100mm

Section : 3.0 to 12.0mm thickness

Round bar size : Diameter: 3-~800mm

Hex Bar size : 2-100mm A/F

Flat bar size : Thickness: 2 -100mm, Width: 10 to 500mm

Rectangles Size : 33 x 30mm to 295 x 1066mm

Hollow Bar : 32mm OD x 16mm ID to 250mm OD x 200mm ID)

Billet Size : 1/2″ to 495mm Diameter

Surface : Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline

Technique : AISI/SAE 4340 alloy steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod

Condition : Hardened & tempered, annealed

Finish : Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black

Form : Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc.

Processing : Bar cutting to 650mm

| Country | USA | Britain | Britain | Japan |

| Standard | ASTM A29 | EN 10250 | BS 970 | JIS G4103 |

| Grades | 4340 | 36CrNiMo4/ 1.6511 |

EN24/817M40 | SNCM 439/SNCM8 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| 5.0 | 45.0 |

| 6.0 | 50.0 |

| 7.0 | 55.0 |

| 8.0 | 60.0 |

| 9.0 | 65.0 |

| 10.0 | 70.0 |

| 12.0 | 75.0 |

| 16.0 | 80.0 |

| 20.0 | 90.0 |

| 25.0 | 100.0 |

| 30.0 | 130.0 |

| 35.0 | 160.0 |

| 40.0 | 200.0 |

HOW TO GET BEST PRICE OF SAE 4340 Round Bars ?

If looking for SAE 4340 Round Rods in exact length so first check Alloy Steel SAE 4340 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Steel Grade (UNS) | C | Si | Mn | P (≤) | S (≤) | Ni | Cr | Mo |

| 4340 alloy steel (UNS G43400) | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | 0.035 | 0.04 | 1.65-2.00 | 0.70-0.90 | 0.20-0.30 |

| AISI 4340 Mechanical Properties | ||||||

| Steel | Condition | Tensile strength, MPa (ksi), ≥ | Yield strength, MPa (ksi), ≥ | Elongation in 50 mm (2 in.), ≥ | Reduction in area, %, ≥ | Hardness, HB, ≤ |

| 4340 | Normalized at 870 °C (1600 °F) | 1282 (186) | 862 (125) | 12.2 | 36.3 | 363 |

| Annealed at 810 °C (1490 °F) | 745 (108) | 470 (68) | 22.0 | 50.0 | 217 | |

| Oil quenched from 800 °C (1475 °F) and tempered at 540 °C (1000 °F) | 1207 (175) | 1145 (166) | 14.2 | 45.9 | 352 | |

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004