Steelo Fabrica is a manufacturing company of EN1A-Leaded Round Bar. Our company also supply these round bars using high quality raw materials. We use new techniques to produce these round bars accurately. Our esteemed clients avail this round bar from us in different sizes that also be customized.

Table of Content

Chemical Composition of EN1A Leaded:

• Carbon

• Manganese

• Silicon

• Sulphur

• Phosphorus

• Lead

What is the EN1A leaded round bar?

We manufacture these round bars in different diameters, thicknesses, different finishes, and surfaces. EN1 Round lead bar can be cemented, which has reasonable strength and ductility and improves wear resistance.EN1A also exhibits a superior finish.

EN1A round bar used in a variety of applications includes Precision machined components, Nuts. Our company offer these round bars has mechanical properties such as Max Stress, yield stress, and elongation. Techniques are hot rolled, cold drawn, cold-rolled and forged used for manufacturing of these round bars. Our company also offer different finishes of these round bars such as polish, bright, smooth turned, centreless ground, etc. Properties of EN1A Leaded Round Bars are good machinability and EN1A leaded round bar Supplied in untreated and cold finished condition. Our company manufacture these round bars are very well known for their properties such as corrosion resistance, dimensional accuracy, easy installation, superior finish, dimensional accuracy and heat resistance.

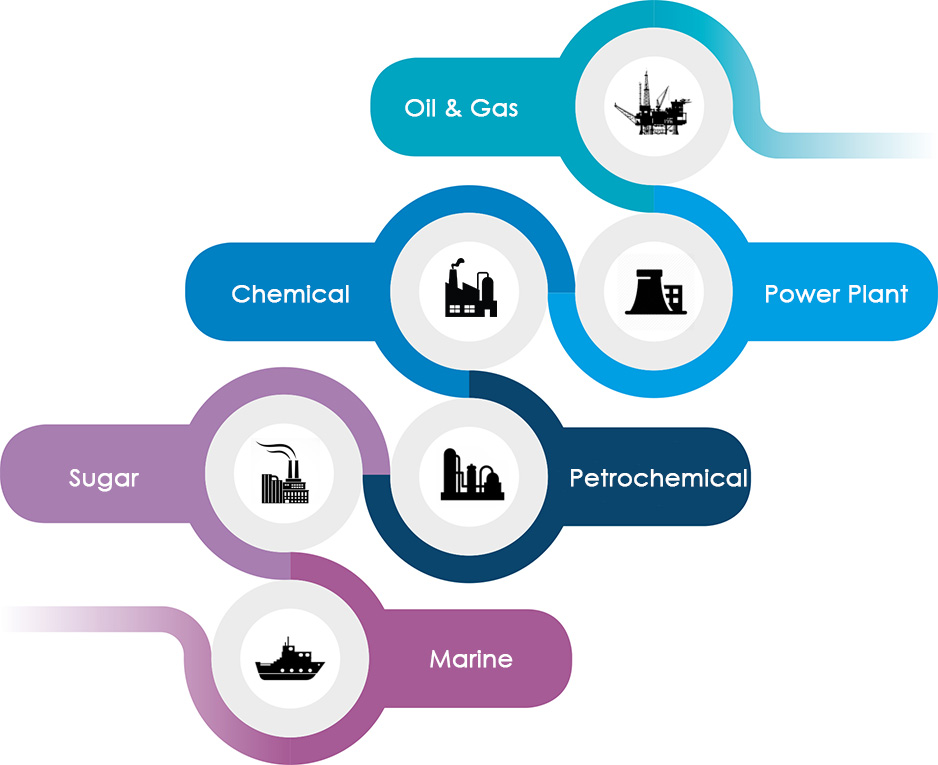

Applications of EN1A Leaded Round bars:

• Chemical Industry

• Plumbing

• Oil and Gas Industry

EN1A Leaded Bars have a good combination of strength, machinability, and wear resistance. The typical mechanical properties include tensile strength of 600-800 N/mm², yield strength of 300-400 N/mm², & elongation of 20-25%.

EN1A Leaded Rods are typically made through a process called hot rolling. This involves heating a billet of steel to a high temperature, & then passing it through a series of rollers to shape it into a round bar. The bar is then cooled and cut to the desired length.

1.0715 Leaded Round Bars have good machinability, which means they are easy to machine & can be shaped into complex parts using a variety of cutting tools.

Grade : EN1APb

Specification: BS970: 1955 EN1A, BS970/PD970: 1970 onwards 230M07.

Round Bar Size : Diameter: 3-~800mm

Square Bar size : 4 to 100mm

Flat Bar Size : Thickness: 2 -100mm, Width: 10 to 500mm

Hex Bar Size : 2-100mm A/F

Rectangles Size : 33 x 30mm to 295 x 1066mm

Hollow Bar : 32mm OD x 16mm ID to 250mm OD x 200mm ID)

Section : 3.0 to 12.0mm thickness

Billet Size : 1/2″ to 495mm Diameter

Finish : Cold (bright) drawn, centreless ground,smooth turned, Rough Turned, Bright, peeled, hot rolled,

hot rolled annealed, slit rolled edge, Polish, Grinding, Centreless Ground & Black

Tolerance : K9, K10, K11, K12, H8, H9, H10, H11, H12, H13, or as per clients’ requirements

Surface : Polished, Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Hairline

Condition : Hardened & Tempered, Annealed

Technique : en1a Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rods

Processing : Bar cutting to 650mm

Form : en1a Welding Bars, Round Bar, Rings, Hollow, Rods, T-Bar, Channel Bar, Flat Bar, Square, Blocks, Precision Ground Bar,

Triangle, Rectangle, Hex (A/F), Threaded, Ingot, I/H Bar, Half Round Bar, Profiles, Billet, Forging etc.

| BS970: 1955 | BS970/PD970: 1970 onwards | European | Werkstoff No. | US SAE (AISI) |

| EN1A | 230M07 | 9SMn28, BS En 11SMn30 | 1.0715 | 1213, 1215 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| Size (ins. dia) | 3/32 | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 11/32 | 3/8 | 7/16 | 1/2 | 17/32 |

| 9/16 | 5/8 | 11/16 | 3/4 | 13/16 | 7/8 | 15/16 | 1 | 1 1/16 | 1 1/8 | 1 3/16 | 1 1/4 | 1 5/16 | |

| 1 3/8 | 1 7/16 | 1 1/2 | 1 5/8 | 1 11/16 | 1 3/4 | 1 7/8 | 2 | 2 1/8 | 2 1/4 | 2 3/8 | 2 1/2 | 2 5/8 | |

| 2 3/4 | 2 7/8 | 3 | 3 1/8 | 3 1/4 | 3 3/8 | 3 1/2 | 3 5/8 | 3 3/4 | 3 7/8 | 4 | 4 1/4 | 4 1/2 | |

| 4 3/4 | 5 | 5 1/4 | 5 1/2 | 5 3/4 | 6 | 6 1/4 | 6 1/2 | 6 3/4 | 7 | 7 1/4 | 7 1/2 | 8 | |

| Size (mm dia) | 2 | 2.5 | 3 | 4 | 5 | 6 | 6.5 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 26 | 28 | |

| 30 | 32 | 35 | 36 | 38 | 40 | 42 | 45 | 46 | 48 | 50 | 52 | 55 | |

| 56 | 58 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 100 | 105 | 110 | 120 | |

| 125 | 130 | 140 | 150 | – | – | – | – | – | – | – | – | – |

| En1A Round Precision Ground Stock | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (ins. dia) | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/4 | 1 3/8 | 1 1/2 | 1 3/4 | 2 | 2 1/4 | 2 1/2 |

| 3 | Tolerances: up to 1″ dia +/- 0.00025″ | |||||||||||||

| Size (mm dia) | 4 | 6 | 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | – |

| Tolerances: to 30mm dia. +0mm/-0.0127mm 35mm to 50mm dia. +0mm/-0.0254mm |

||||||||||||||

| En1A Round Hot Rolled | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (mm dia) | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 |

| 130 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | 180 | 190 | 200 | 210 | 220 | |

| En1A Hexagon Bright Drawn | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (ins. A/F) | 0.193 | 0.248 | 0.312 | 0.324 | 0.375 | 0.437 | 0.445 | 0.500 | 0.525 | 0.562 | 0.600 | 0.625 | 0.687 | 0.710 | |||

| 0.750 | 0.812 | 0.820 | 0.875 | 0.920 | 0.937 | 1.000 | 1.010 | 1.062 | 1.100 | 1.125 | 1.200 | 1.250 | 1.300 | ||||

| 1.312 | 1.480 | 1.500 | 1.625 | 1.670 | 1.860 | 2.050 | 2.220 | 2.410 | 2.580 | 2.760 | 3.150 | 3.550 | – | ||||

| Size (mm A/F) | 5 | 6 | 7 | 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | |||

| 20 | 22 | 24 | 25 | 26 | 27 | 30 | 32 | 35 | 36 | 41 | 46 | 50 | 55 | ||||

| 60 | 65 | 70 | 75 | – | – | – | – | – | – | – | – | – | – | ||||

| En1A Squares Bright Drawn | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (ins. sq) | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 |

| 1 1/2 | 1 3/4 | 2 | 2 1/4 | 2 3/4 | 3 | 3 1/4 | 3 1/2 | 4 | – | – | – | – | – | |

| Size (mm sq) | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 15 | 16 | 18 | 20 | 22 | 25 | 30 |

| 32 | 40 | 45 | 50 | 60 | – | – | – | – | – | – | – | – | – | |

| En1A Mild Steel Metric Flats | |

|---|---|

| 10 mm | 3, 5 mm |

| 12 mm | 3, 5, 6 mm |

| 13 mm | 3 mm |

| 16 mm | 3 mm |

| 20 mm | 3, 5, 6, 8, 10, 12 |

| 25 mm | 3, 5, 6, 8, 10, 12, 16, 20 |

| 30 mm | 3, 5, 6, 8, 10, 12, 16, 20, 25 |

| 40 mm | 3, 5, 6, 8, 10, 12, 16, 20, 25, 30 |

| 50 mm | 3, 5, 6, 8, 10, 12, 16, 20, 25, 30 |

| 60 mm | 3, 6, 8, 10, 12, 16, 20, 25, 30 |

| 70 mm | 3, 5, 6, 8, 10, 12, 16, 20, 25 |

| 80 mm | 5, 6, 8, 10, 12, 16, 20, 25 |

| 90 mm | 6, 10, 12, 16 |

| 100 mm | 3, 5, 6, 8, 10, 12, 16, 20, 25, 30, 40, 50 |

| 125 mm | 10, 25, 50 |

| 150 mm | 6, 10, 12, 16, 20, 25, 30, 40, 50 |

| 200 mm | 10, 12, 20, 25, 30, 50 |

HOW TO GET BEST PRICE OF EN1A Leaded Round Bars ?

If looking for EN1A Leaded Round Bars in exact length so first check Carbon Steel EN1A Leaded price per KG in India and calculate with wight chart before negotiating with your supplier.

| Grade | Chemical composition %: | |||||||

| C | Si | Mn | P | S | ||||

| EN1A | max 0.14 | max 0.05 | 0.9 – 1.3 | max 0.11 | 0.27 – 0.33 | |||

| Nominal thickness (mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 63 | 63 – 100 |

| Rm – Tensile strength (MPa) (+C) | 510-810 | 490-760 | 460-710 | 400-650 | 360-630 |

| Nominal thickness(mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 63 | 63 – 100 |

| Rp0.2 0.2% proof strength (MPa) (+C) | 440 | 410 | 375 | 305 | 245 |

| Nominal thickness (mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 100 |

| A – Min. elongation at fracture (%) (+C) | 6 | 7 | 8 | 9 |

| Brinell hardness (HBW): (+SH) | 107 – 169 |

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004