Steelo Fabrica is a leading manufacturer, supplier and exporter of EN1A- Leaded Hexagon Bars. We manufacture these round bars using the highest quality raw materials. Customers can purchase any size, length, and width of hexagonal bars from us. We use modern machinery to produce these bars. Our hexagonal bar has high demand in the market due to its accurate dimensions, long service life and durability.

Table of Content

What is EN1A-Leaded Hexagon Bar?

Hexagonal Bars are accurately shaped for items or machines that require accurate pieces. One of the most common places where they are used is conveyor tables. Hexagonal bars are generally easy to drill and shape, making them common in braces, ornamental, and interior work. This hexagonal bar has moderate weldability and good machinability. Added lead in this alloy to improve machinability. It made little changes in the mechanical properties of these bars.

Key features of EN1A-Leaded Hexagon Bars:

• Used in intricate drilling & machining operations

• Can be cemented for better wear

• Superior resistance finish

• Reasonable strength and ductility

• Non-corrosive

• High tensile strength

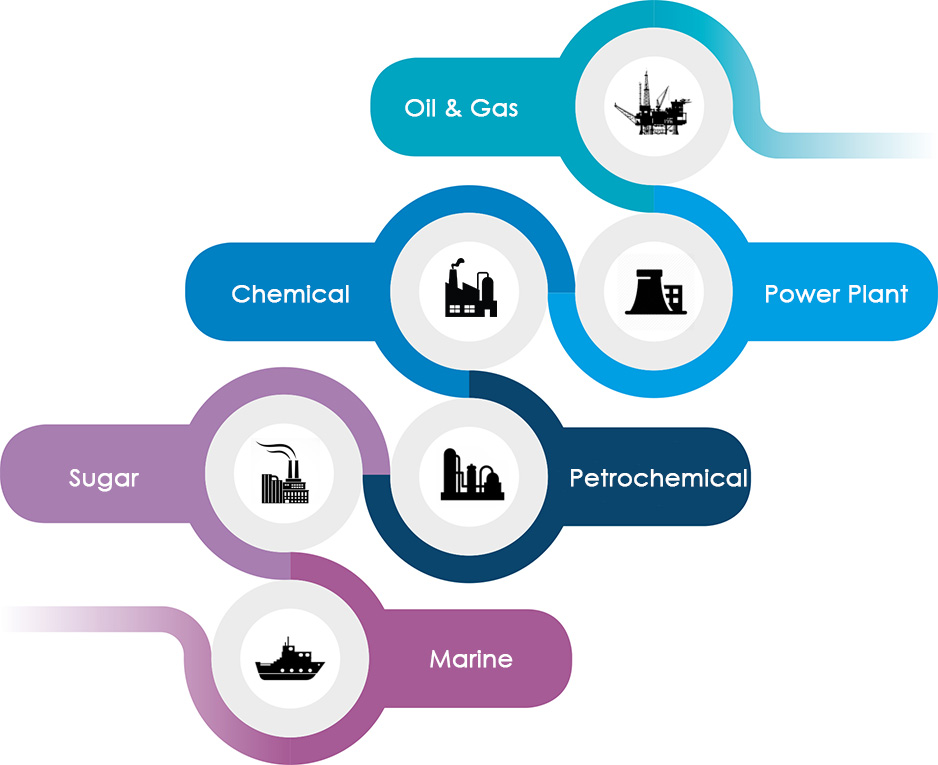

Applications of EN1A-Leaded Hexagon Bars:

Our company provide these EN1A-Leaded Hexagonal Bars that can be used in a broad range of commercial applications, which include: Control linkages, shafts, low-stress hubs, casings and handles. Brake hose ends, hydraulic parts. Brake pistons, wheel nuts and inserts.

EN1A Leaded Hexagon Bars are manufactured using steel alloy that contains a small amount of lead & small amounts of other elements such as carbon, manganese, & sulfur. These bars are commonly used in the manufacturing of precision components.

EN1A Leaded Hex Bars can be welded, but care must be taken due to the presence of lead. It is recommended to use low-hydrogen welding methods & to preheat the bars before welding to prevent cracking.

En1A Leaded Hex Bright Bars are used in the manufacturing of precision components such as gears, shafts, & other machinery parts. Other industrial components like bolts, fasteners, and bushings are also manufactured using them. EN1A leaded hexagon bars are commonly used in general engineering, automotive & aerospace industries.

Grade : EN1A

Specification: BS970: 1955 EN1A, BS970/PD970: 1970 onwards 230M07.

Hexagon Bar Size : Diameter: 3-~800mm

Hex Bar Size : 2-100mm A/F

Finish : Cold (bright) drawn, centreless gHexagon,smooth turned, Rough Turned, Bright, peeled, hot rolled,

hot rolled annealed, slit rolled edge, Polish, Grinding, Centreless GHexagon & Black

Tolerance : K9, K10, K11, K12, H8, H9, H10, H11, H12, H13, or as per clients’ requirements

Surface : Polished, Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Hairline

Condition : Hardened & Tempered, Annealed

Technique : en1a Hot Rolled, Cold Rolled, Cold Drawn, Hexagon Bar, Rods

Processing : Bar cutting to 650mm

| BS970: 1955 | BS970/PD970: 1970 onwards | European | Werkstoff No. | US SAE (AISI) |

| EN1A | 230M07 | 9SMn28, BS En 11SMn30 | 1.0715 | 1213, 1215 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| En1A Hexagon Bright Drawn | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (ins. A/F) | 0.193 | 0.248 | 0.312 | 0.324 | 0.375 | 0.437 | 0.445 | 0.500 | 0.525 | 0.562 | 0.600 | 0.625 | 0.687 | 0.710 | |||

| 0.750 | 0.812 | 0.820 | 0.875 | 0.920 | 0.937 | 1.000 | 1.010 | 1.062 | 1.100 | 1.125 | 1.200 | 1.250 | 1.300 | ||||

| 1.312 | 1.480 | 1.500 | 1.625 | 1.670 | 1.860 | 2.050 | 2.220 | 2.410 | 2.580 | 2.760 | 3.150 | 3.550 | – | ||||

| Size (mm A/F) | 5 | 6 | 7 | 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | |||

| 20 | 22 | 24 | 25 | 26 | 27 | 30 | 32 | 35 | 36 | 41 | 46 | 50 | 55 | ||||

| 60 | 65 | 70 | 75 | – | – | – | – | – | – | – | – | – | – | ||||

HOW TO GET BEST PRICE OF EN1A Leaded Hexagon Bars ?

If looking for EN1A Leaded Hexagon Bars in exact length so first check Carbon Steel EN1A Leaded Bar price per KG in India and calculate with wight chart before negotiating with your supplier.

| Grade | Chemical composition %: | |||||||

| C | Si | Mn | P | S | ||||

| EN1A | max 0.14 | max 0.05 | 0.9 – 1.3 | max 0.11 | 0.27 – 0.33 | |||

| Nominal thickness (mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 63 | 63 – 100 |

| Rm – Tensile strength (MPa) (+C) | 510-810 | 490-760 | 460-710 | 400-650 | 360-630 |

| Nominal thickness(mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 63 | 63 – 100 |

| Rp0.2 0.2% proof strength (MPa) (+C) | 440 | 410 | 375 | 305 | 245 |

| Nominal thickness (mm): | 5 – 10 | 10 – 16 | 16 – 40 | 40 – 100 |

| A – Min. elongation at fracture (%) (+C) | 6 | 7 | 8 | 9 |

| Brinell hardness (HBW): (+SH) | 107 – 169 |

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004