The manufacturing company Steelo Fabrica focuses on the production of the SAE – 4140 round bars and rods. We manufacture the products range from SAE – 4140, serving mainly in construction and engineering fields.

Table of Content

Chemical composition of the SAE – 4140 round rods:

• Carbon

• Manganese

• Chromium

• Nickel

• Silicon

• Sulfur

• Phosphorus

What are the properties that these round bars have?

SAE 4140 is a chromium molybdenum alloy steel that is widely used in the oil and gas industry. The greater carbon content in SAE 4140 material offers higher strength and heat treatment capabilities.

Apart from strength, it also has a suitable weldability property and machinability. In addition, greater carbon content gives higher rigidity; thus, it is primarily used in sectors where greater rigidity and resistance are required over lower carbon grades.

These round bars have a higher fatigue strength, toughness, abrasion, torsional strength, and impact resistance. It should be well heat treated in various ways to give it a combination of properties.

These round bars offer excellent resistance against rust. Due to this property, it is used in rustic conditions. In addition, because of the many efficient features and characteristics, our high-quality SAE 4041 round bars can be utilized in high-corrosive environments.

These Round bars can sustain pitting and crevice corrosion. All these properties listed above make these round bars suitable for many industrial applications.

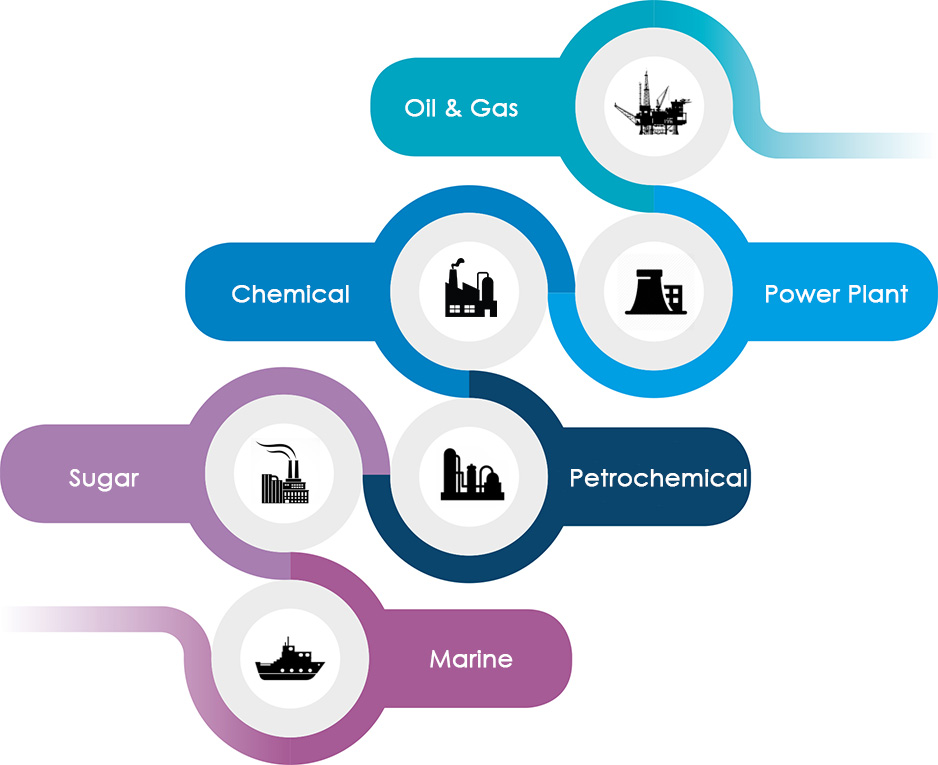

What are the sectors in which these round rods are highly applicable?

Few applications of the round bars are Adapters, Arbor’s, Axle Shafts, Connection Rods, Ejector Pins, Forks, Gears, Guide Rods, Hydraulic Shafts & Parts, Lathe Spindles, Bolts, Nuts.

Some of the above applications are used in sectors like Power plants, engineering solutions, Food processing units, Water supply channels, Structural pipes, Plumbing, chemical industry, heat exchangers, etc.

ASTM A-29

ASME SA-29

DIN

1.7225

UNS G41400

Specification : ASTM A29, ASME SA29

Grade: 4140

Specification : Alloy Steel 4140 Bar

Square bar size : 4 to 100mm

Section : 3.0 to 12.0mm thickness

Round bar size : Diameter: 3-~800mm

Hex Bar size : 2-100mm A/F

Flat bar size : Thickness: 2 -100mm, Width: 10 to 500mm

Rectangles Size : 33 x 30mm to 295 x 1066mm

Hollow Bar : 32mm OD x 16mm ID to 250mm OD x 200mm ID)

Billet Size : 1/2″ to 495mm Diameter

Surface : Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline

Technique : AISI/SAE 4140 alloy steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod

Condition : Hardened & tempered, annealed

Finish : Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black

Form : Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc.

Processing : Bar cutting to 650mm

| Country | USA | German | British | Japan | China | Australia |

| Standard | ASTM A29 | DIN 17200 | BS 970 | JIS G4105 | GB/T 3077 | AS 1444 |

| Grades | 4140 | 1.7225/ 42crmo4 |

42CrMo4 | SCM440 | 42CrMo | 4140 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| 5.0 | 45.0 |

| 6.0 | 50.0 |

| 7.0 | 55.0 |

| 8.0 | 60.0 |

| 9.0 | 65.0 |

| 10.0 | 70.0 |

| 12.0 | 75.0 |

| 16.0 | 80.0 |

| 20.0 | 90.0 |

| 25.0 | 100.0 |

| 30.0 | 130.0 |

| 35.0 | 160.0 |

| 40.0 | 200.0 |

HOW TO GET BEST PRICE OF SAE 4140 Round Bars ?

If looking for SAE 4140 Round Rods in exact length so first check Alloy Steel SAE 4140 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A29 | 4140 | 0.38-0.43 | 0.75-1.00 | 0.035 | 0.040 | 0.15-0.35 | – | 0.8-1.10 | 0.15-0.25 |

| EN 10250 | 42CrMo4/ 1.7225 |

0.38-0.45 | 0.6-0.9 | 0.035 | 0.035 | 0.4 | – | 0.9-1.2 | 0.15-0.30 |

| JIS G4105 | SCM440 | 0.38-0.43 | 0.60-0.85 | 0.03 | 0.03 | 0.15-0.35 | – | 0.9-1.2 | 0.15-0.30 |

| Properties | Metric | Imperial |

| Tensile strength | 655 MPa | 95000 psi |

| Yield strength | 415 MPa | 60200 psi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.70% | 25.70% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (based on AISI 1212 as 100 machinability) | 65 | 65 |

Products

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004