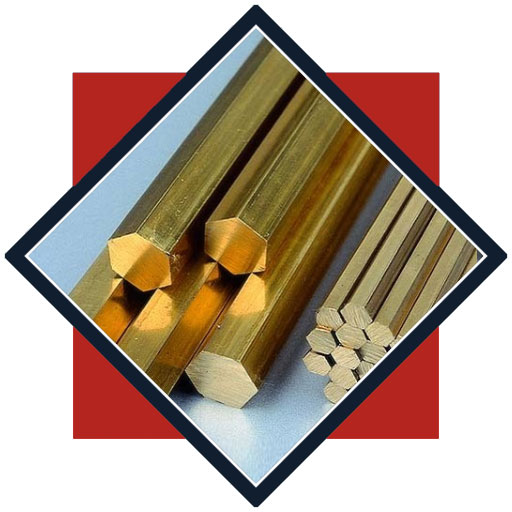

We at Steelo Fabrica supply and high import quality Forging Brass CW617N Forged Bar. In our company, customers can buy these forged bars as per their needs. Specifications of these forging brass CW617N rods are lengths, width, thickness, diameters and standards. These forged bars are accurate in shape because we use new machinery and techniques. We have an in-house testing service to test the raw materials before using them for the manufacturing process. All our products are mostly suggested by our clients due to their reliability, and it has come at cost-effective prices.

Table of Content

Chemical Composition of forging Brass CW617N Forged Bar:

• Copper

• Lead

• Iron

• Zinc

Why is Forging Brass CW617N alloy used?

CW617N is the most commonly used alloy because changes in shapes are very easy with this alloy using processes like the hammering process. This alloy has the ability for hot forming and also has good machinability properties. CW617N alloy shows a good combination of hot working and machining properties.

What is Forging Brass CW617N Forged Bar?

These forged bars are made using main components like zinc and copper. These bars are easily changed their shape, and it is found in various colours. Our company design these rods has high thermal conductivity. This forged bar has good forge-ability. Our forging brass CW617N forged bar can be handle a stronger impact, and it has greater durability. Our company manufacturer could also coat these rods with a chromium coating, which then shows a natural bond with the alloy, thus effectively preventing the Forged Brass bars from getting dull. These bars are manufactured by processes such as hot working, cold working or annealing. These rods are highly resistant to corrosion.

Forging Brass CW617N

Forged Bar shows mechanical properties:

• Melting point

• Density

• Thermal expansion coefficient

• Electrical conductivity

• Electrical resistivity

Applications of Forging Brass CW617N Forged Bars:

• Automotive components

• Architectural hardware

• Speciality hardware

Specification : ASTM / ASME

Standards : BS 218, IS – 6912/2005 FLB, Modified Forging Brass Rods as per IS – 8737, CW 617 N EN 12164 : 1998, CDA 377

Size : 6 to 60mm

Thickness : 0 274 mm to 6.35 mm

DIAMETER : 62 mm

LENGTH : 69 mm

WEIGHT : ≈ 25.35 kg/m

Form : Forged, Square, Hex (A/F), Rectangle Etc.

| EU EN |

Germany DIN,WNr |

Russia GOST |

| CuZn40Pb2 | CuZn40Pb2 2.0402 |

LS59-2 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

HOW TO GET BEST PRICE OF Forging Brass CW617N Forged BAR ?

If looking for Forging Brass CW617N Forged Bars and Rod in exact length so first check Copper Zinc Alloy CW617N Forged Bars price per KG in India and calculate with wight chart before negotiating with your supplier.

| Fe | Ni | Al | Cu | Pb | Sn | Others | – |

| max 0.3 | max 0.3 | max 0.05 | 57 – 59 | 1.6 – 2.5 | max 0.3 | total 0.2 | Zn – remainder |

| Rm – Tensile strength (MPa) (R380) | 380 |

| Rm – Tensile strength (MPa) (R430) | 430 |

| Rp0.2 0.2% proof strength (MPa) (R380) | 160 |

| Rp0.2 0.2% proof strength (MPa) (R430) | 250 |

| A – Min. elongation at fracture (%) (R380) | 18 |

| A – Min. elongation at fracture (%) (R430) | 10 |

| A – Min. elongation Lo = 100mm (%) (R430) | 6 |

| Brinell hardness (HB): (R380) | 90 |

| Brinell hardness (HB): (R430) | 120 |

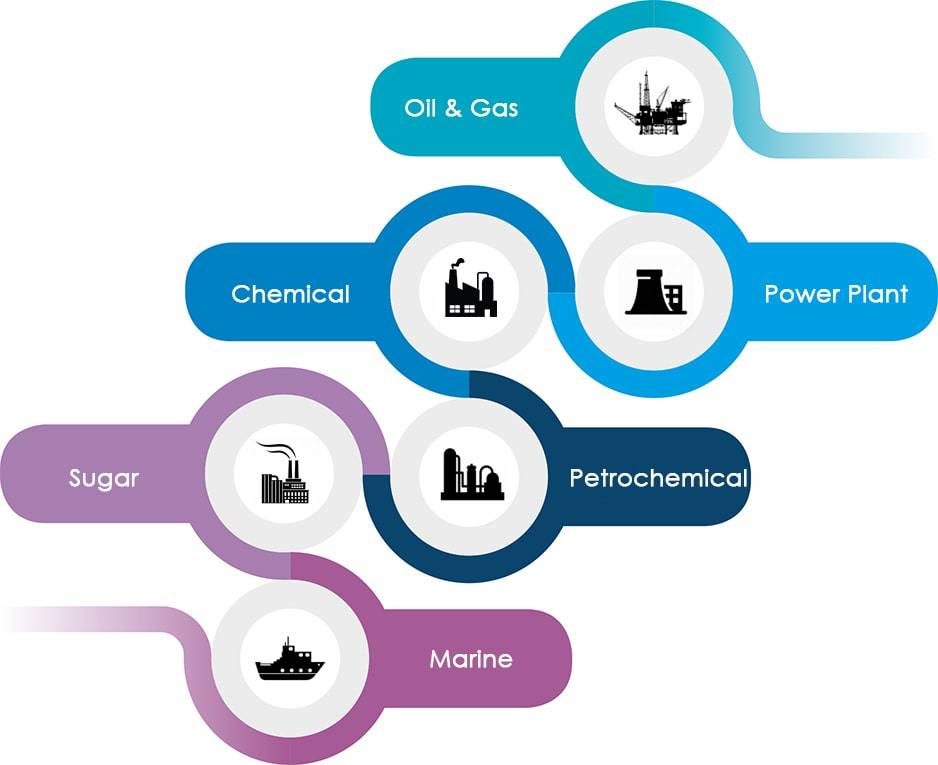

We offer a broad range of Forging Brass CW617N Forged Bars through a worldwide network of stock-keeping branches. These CW617N Forging Brass Forged Bars is use in various industries like :

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004