Steelo Fabrica is known for widespread supply and is an experienced manufacturer of Inconel 625 Round Bar. We are engaged in large production of these Bars with a diverse range. While producing these bars, we assure to maintain standards and quality according to the universal designation. We introduce sizes and forms of these Round Bars with different finishes. Our clients acclaim the proficiency and serviceability of the Bar and specify cold-drawn bar, hot rolled Bar, annealed bar, bright polished Bar, matte-finished Bars to use in different applications.

Table of Content

Inconel 625 and Inconel 625 Round Bar:

Inconel 625 is a Niobium-stabilized grade of Nickel-Chromium alloy implemented for strength and aqueous corrosion protection. It is included alloying elements Carbon, Iron, Manganese, and Silicon and is improved with the addition of Aluminium, Titanium, Molybdenum, and Niobium. It is excellent working against pitting, crevice corrosion and is proposed for acid and high-temperature surroundings.

Characteristics:

• Fatigue strength

• Superior mechanical strength

• Aqueous corrosion-proof

• Anticorrosive

• Resists erosion at elevated temperatures

Inconel 625 Round Bar is a solid and robust Bar with a brilliant combination of strength and resistance to corrosion as well as heat. It is widely selected for long time use in severe conditions.

• The Bar is efficiently working at a higher temperature without stress cracking due to increased strength.

• Niobium is the key element that hardens the alloy matrix with Molybdenum. Thus these Bars are hardened and give stability in extreme conditions.

• These Bars possess toughness at stress conditions and prevents cracking of the Bar.

• These Bars are versatile and formable, with excellent mechanical properties.

• It shows improved tensile strength and outstanding high-temperature strength.

Inconel 625 Round Bar resists general corrosion, crevice cracking, and corrosion cracking. These Bars are more efficient in resisting aqueous corrosion in brine and stream water. They are not disintegrated in brine surroundings and retain durable structure and strength. We recommend these bars in acerbic environments with outstanding resistance to organic acids. They are immune to chloride ion corrosion and cracking, improving creep strength. These Bars are readily welded with conventional techniques.

Applications of Inconel 625 Round Bar:

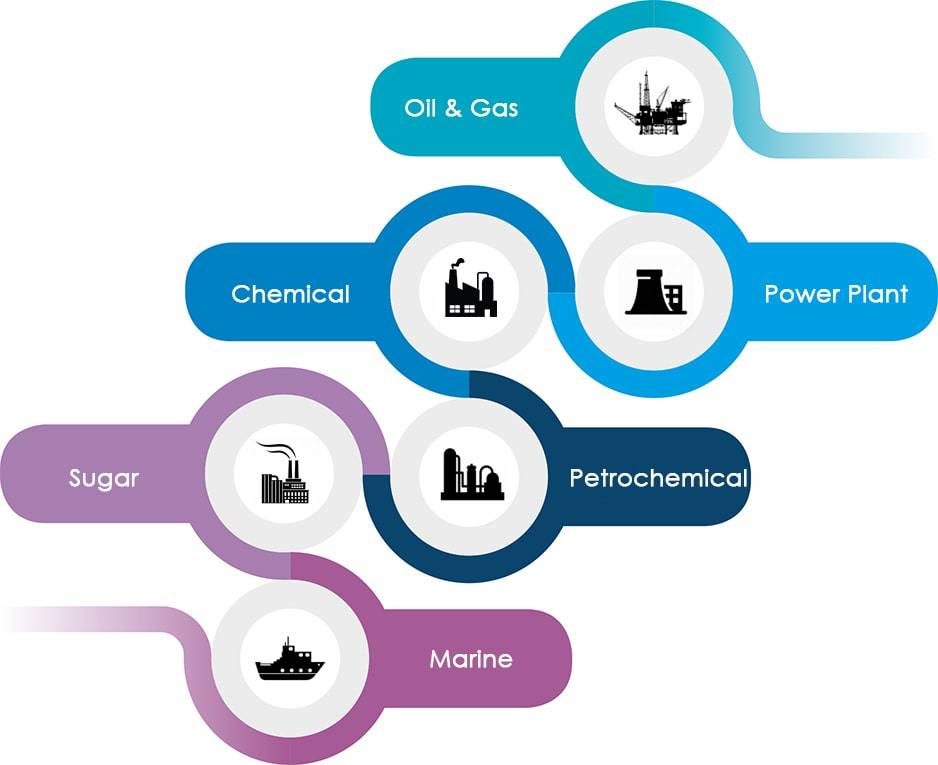

• Aircraft Duct, Jet Engine

• Aerospace, Chemical Industry

• Seawater apparatus

• Offshore Oil Industries

Specification : ASTM B446/ ASME SB446

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Round Bars : Outside Diameter in the range of 4mm to 500mm

Bright Bars : Outside Diameter in the range of 4mm to 100mm

Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″)

Square Bars : 18mm – 47mm (11/16″ to 1-3/4″)

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Length : 1 to 6 Meters, Custom Cut Lengths

Form : Round, Square, Hex (A/F), Rectangle Etc.

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Inconel 625 | 2.4856 | N06625 | ХН75МБТЮ | NC22DNB4M | NCF 625 | NA 21 | NiCr22Mo9Nb | ЭИ602 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| Inconel 625 Round bar Type | SIZES (mm) | SIZES (Inches) | ISO Tolerance |

|---|---|---|---|

| Alloy 625 Cold Drawn and Polish Round Bar | 3.00 – 75.00 | 1/8″ – 3.00″ | h8-h9-h10-h11 |

| Nickel Alloy 625 Cold Drawn and Ground Bar | 10.00 – 75.00 | 5/6″ – 2.50″ | h8-h9-h10-h11 |

| UNS N06625 Peeled and Polished Round Bar | 40.00 – 150.00 | 1.50″ – 6.00″ | h11, h11-DIN 1013 |

| Inconel 625 Peeled and Ground Bar | 20.00 – 50.00 | 3/4″ – 2.00″ | h9-h10-h11 |

| Inconel 625 Round bar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

HOW TO GET BEST PRICE OF Inconel 625 ROUND BAR ?

If looking for Alloy Bars and Rod in exact length so first check Inconel 625 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Grade | Ni | Cr | Fe | C | Mn | Si | Mo | Co | Al | Ti | Nb + Ta | P | S |

| Inconel 625 | 58.0 min | 20.0 – 23.0 | 5.0 max | 0.10 max | 0.50 max | 0.50 max | 8.0 – 10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15 – 4.15 | 0.015 max | 0.015 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

We offer a broad range of ASTM B446 Inconel 625 Round Bars through a worldwide network of stock-keeping branches. These 625 Inconel Round Bar is use in various industries like :

Morocco, Sweden, Qatar, Iraq, Bolivia, Switzerland, Ghana, Thailand, Serbia, Mexico, Croatia, Lithuania, New Zealand, Oman, Spain, Finland, South Africa, Mexico, Colombia, Tunisia, Australia, Bulgaria, Kuwait, Poland, Ukraine, Japan, Angola, Afghanistan, Slovakia, Iran, Mongolia, France, Lebanon, Canada, Ecuador, China, Venezuela, Greece, Kenya, Libya, Malaysia, Portugal, Sri Lanka, Poland, Jordan, Belarus, South Korea, Romania, United Kingdom, Philippines, Algeria, Chile, Hungary, Denmark, Hong Kong, Bhutan, Egypt, Bangladesh, Saudi Arabia, United Arab Emirates, United States, Pakistan, Argentina, Gabon, Italy, Netherlands, Taiwan, Chile, Indonesia, RuInconel ia, Costa Rica, Turkey, Norway, Kazakhstan, Nigeria, Czech Republic, Nigeria, Estonia, Azerbaijan, Vietnam, Austria, Iran, Trinidad & Tobago, Bahrain, Peru, Yemen, Belgium, Israel, Brazil, Singapore.

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004