We at Steelo Fabrica manufacture a varied range of products for numerous industrial applications. Our products like Nitronic 60 forged Bars are known to provide the best utility in all utilization conditions, and our rods are best known for their wear resistance.

These forged bars and rods are mainly used for connecting components for the transmission of work. It has higher strength than powder metallurgy rod.

Chemical composition:

The chemical composition of the stainless steel nitronic 60 forged bars consist of Chromium, manganese, nickel, silicon, carbon, iron, nitrogen. It is silicon and manganese alloyed austenitic stainless steel with doubled yield strength.

Nitronic 60 rods are made with a fully austenitic alloy, and it was originally designed as a temperature alloy in many manufacturing industries.

Table of Content

Properties that these rods hold:

These stainless steel nitronic 60 rods provide a significantly lower cost way to resist against wear compared with cobalt-wearing and high nickel alloys.

The nitrogen addition in these rods enhances the strength internally rather than nitride on the surfaces as some steel materials are treated.

These stainless steel nitronic 60 rods are mainly known for their excellent galling resistance at elevated temperature ranges. These forged bars are nitrogen strengthened stainless steel with amazing strength and wear resistivity.

It has good lower temperature impact property and retention of strength at elevated temperatures range. Its uniform corrosion resistance offers a real high-temperature oxidation resistance as well.

Applications of the nitronic 60 rods:

ASTM A-276

ASME SA-276

UNS S21800

WNR. ---

Specification : ASTM A276 / ASME SA276

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 1000 MM TO 7000 MM

Outer Diameter : 100MM TO 400 mm Max OD

Weight : 1000 to 6000 Kg

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Tolerance : 0/+2-3mm

| STANDARD | UNS | WERKSTOFF NR. |

| Nitronic 60 | S21800 | – |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

|---|---|---|---|---|---|---|---|

| Diameter(Inch) | Size | Diameter (millimeter) | Size | Diameter (millimeter) | Size | Diameter (millimeter2) | Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 0.062 | 0.019 | 22 millimeter | 2.979 | 0.908 | 3 to 1/4″ | 41.996 | 12.800 |

| 3 millimeter | 0.055 | 0.017 | 20 millimeter | 2.470 | 0.753 | 3″ | 35.762 | 10.900 |

| 4 millimeter | 0.098 | 0.030 | 24 millimeter | 3.543 | 1.080 | 3 to 3/4″ | 55.780 | 17.001 |

| 5/32″ | 0.095 | 0.029 | 7/8″ | 3.038 | 0.926 | 3 to 1/2″ | 48.772 | 14.850 |

| 5 millimeter | 0.154 | 0.047 | 1″ | 3.970 | 1.210 | 4 to 1/4″ | 72.249 | 21.908 |

| 3/16″ | 0.141 | 0.043 | 25 millimeter | 3.871 | 1.180 | 4″ | 63.340 | 19.306 |

| 6 millimeter | 0.223 | 0.068 | 27 millimeter | 4.490 | 1.368 | 4 to 3/4″ | 90.249 | 27.366 |

| 7/32″ | 0.190 | 0.058 | 26 millimeter | 4.170 | 1.271 | 4 to 1/2″ | 80.340 | 24.4487 |

| 7 millimeter | 0.298 | 0.091 | 30 millimeter | 5.548 | 1.691 | 5 to 1/2″ | 121.000 | 36.690 |

| 1/4″ | 0.249 | 0.076 | 1 to 1/8″ | 5.033 | 1.534 | 5″ | 99.940 | 30.461 |

| 8 millimeter | 0.398 | 0.120 | 32 millimeter | 6.314 | 1.894 | 6 to 1/2″ | 167.630 | 51.093 |

| 5/16″ | 0.387 | 0.118 | 1 to 1/4″ | 6.349 | 1.924 | 6″ | 143.900 | 43.860 |

| 3/8″ | 0.557 | 0.170 | 35 millimeter | 7.553 | 2.390 | 7 to 1/2″ | 225.000 | 68.226 |

| 9 millimeter | 0.498 | 0.152 | 1 to 3/8″ | 7.550 | 2.303 | 7″ | 196.000 | 59.432 |

| 11 millimeter | 0.748 | 0.228 | 38 millimeter | 8.903 | 2.792 | 10″ | 397.140 | 121.048 |

| 10 millimeter | 0.620 | 0.189 | 36 millimeter | 7.999 | 2.438 | 8″ | 254.55 | 77.586 |

| 12 millimeter | 0.889 | 0.271 | 40 millimeter | 9.872 | 3.009 | |||

| 7/16″ | 0.761 | 0.232 | 1 to 1/2″ | 8.951 | 2.715 | |||

| 13 millimeter | 1.043 | 0.318 | 1 to 3/4″ | 12.179 | 3.712 | |||

| 1/2″ | 0.994 | 0.303 | 1 to 5/8″ | 10.449 | 3.200 | |||

| 9/16″ | 1.256 | 0.383 | 1 to 7/8″ | 13.977 | 4.260 | |||

| 14 millimeter | 1.207 | 0.368 | 45 millimeter | 12.555 | 3.807 | |||

| 5/8″ | 1.551 | 0.473 | 50 millimeter | 15.414 | 4.698 | |||

| 15 millimeter | 1.391 | 0.424 | 48 millimeter | 14.205 | 4.330 | |||

| 17 millimeter | 1.791 | 0.543 | 2 to 1/8″ | 17.963 | 5.475 | |||

| 16 millimeter | 1.578 | 0.481 | 2″ | 15.906 | 4.848 | |||

| 18 millimeter | 2.001 | 0.610 | 60 millimeter | 22.205 | 6.768 | |||

| 11/16″ | 1.880 | 0.573 | 2 to 1/4″ | 20.128 | 6.135 | |||

| 3/4″ | 2.237 | 0.682 | 2 to 3/8″ | 22.435 | 6.838 | |||

| 2 to 1/2″ | 24.856 | 7.576 | ||||||

| 2 to 5/8″ | 27.409 | 8.354 | ||||||

| 2 to 3/4″ | 30.083 | 9.169 |

HOW TO GET BEST PRICE OF SS Nitronic 60 FORGED BAR ?

If looking for Nitronic 60 Forged Bars and Rod in exact length so first check SS Nitronic 60 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Grade | C | Ni | Si | Mn | Cr | Mo | S | |

| Nitronic 60 | min. | – | 8.00 | 3.5 | 7.00 | 16.00 | – | – |

| max. | 0.10 | 9.00 | 4.5 | 9.00 | 18.00 | 0.75 | – |

| Grade | Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min | Hardness |

| Nitronic 60 | 105 | 35 | 55 | – |

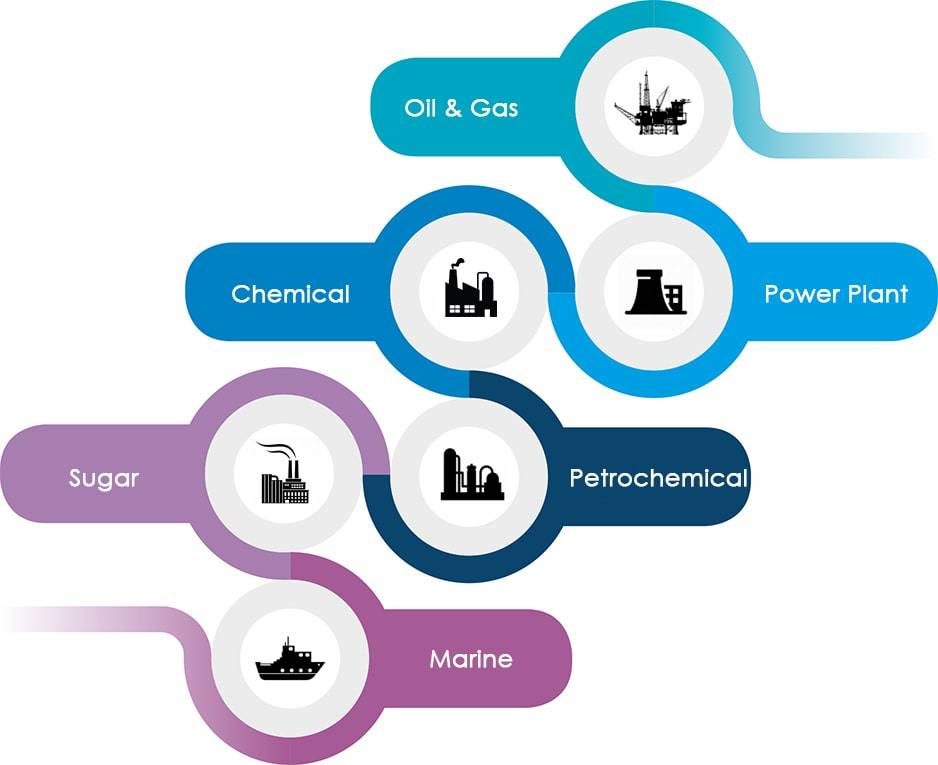

We offer a broad range of ASTM A276 SS Nitronic 60 Forged Bars through a worldwide network of stock-keeping branches. These Nitronic 60 Stainless Steel Forged Rods is use in various industries like :

Products

Hyderabad, Vadodara, Madrid, Doha, Algiers, Houston, Dallas, Aberdeen, Ranchi, Cairo, Secunderabad, Jeddah, Howrah, Al Jubail, Bogota, Milan, Seoul, Rajkot, Pune, Jaipur, Muscat, Courbevoie, Ernakulam, Navi Mumbai, Nagpur, Granada, Kanpur, Kuwait City, Mumbai, Atyrau, Dammam, Visakhapatnam, Bhopal, Karachi, Coimbatore, Baroda, Port-of-Spain, Surat, Melbourne, Manama, Riyadh, Thiruvananthapuram, Chandigarh, Toronto, Calgary, Rio de Janeiro, Ludhiana, Pimpri-Chinchwad, Jamshedpur, Noida, Ahmedabad, Abu Dhabi, Thane, Caracas, Ho Chi Minh City, Indore, Ahvaz, Haryana, Faridabad, Chiyoda, New York, Jakarta, Bangkok, Chennai, Ankara, Tehran, Nashik, Sharjah, Kolkata, New Delhi, Istanbul, Gurgaon, Lagos, Ulsan, Brisbane, Bengaluru, Busan, Edmonton.

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004