Welcome to the world of high-quality Custom 465 Stainless Steel Bar, carefully crafted to meet the most demanding industrial requirements. Our Stainless Steel Custom 465 Forged Rods testify to precision engineering and superior metallurgy for exceptional application performance. Also known as SS Custom 465 Forged Bars or Stainless Steel Custom 465 Forged Bar, these bars demonstrate durability, corrosion resistance and strength.

The finely crafted UNS S46500 Forged Bar is a standout item in our collection. Designed to meet and exceed industry standards, the Custom UNS S46500 forged bar is the perfect choice for critical applications. Made of stainless steel, the Custom 465 Stainless Steel Forged Bar offers the perfect balance of mechanical properties, making them suitable for demanding environments. Our commitment to quality is further reflected in the SS Custom 465 Forged Rod, ensuring reliability and longevity.

Table of Content

Compliant with ASTM F899 benchmarks, our Custom 465 Stainless Forged Rods ensure top-notch execution. Whether you would like ASTM F899 UNS S46500 Stainless Steel Bars or ASTM F899 UNS S46500 Forged Bars, we have you secured. The Custom UNS S46500 Forged Rod is built for brilliance, giving a vigorous solution for assorted mechanical needs. Believe in the exactness and quality of our Stainless Steel Grade Custom 465 Bar, conveying unparalleled execution.

Investigate the flexibility of our item extension, counting UNS S46500 Manufactured Bars and UNS S46500 Stainless Steel Forged Bars. The Stainless Steel Review Custom 465 Poles offer remarkable quality and erosion resistance, making them vital in different applications. As a driving Stainless Steel Custom 465 Bar Producer by Steelo Fabrica, we are a trusted supplier in Mumbai, India. Hoist your ventures with our Stainless Steel Custom 455 Round Bars and Stainless Steel Custom 455 Forged Bars, exhibiting the same commitment to excellence that characterizes our whole item run.

Specification : ASTM F-899 / AMS 5617

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 1000 MM TO 7000 MM

Outer Diameter : 100MM TO 400 mm Max OD

Weight : 1000 to 6000 Kg

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Tolerance : 0/+2-3mm

| STANDARD | Material No | UNS |

| Custom 465 | – | S46500 |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

|---|---|---|---|---|---|---|---|

| Diameter(Inch) | Size | Diameter (millimeter) | Size | Diameter (millimeter) | Size | Diameter (millimeter2) | Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 0.062 | 0.019 | 22 millimeter | 2.979 | 0.908 | 3 to 1/4″ | 41.996 | 12.800 |

| 3 millimeter | 0.055 | 0.017 | 20 millimeter | 2.470 | 0.753 | 3″ | 35.762 | 10.900 |

| 4 millimeter | 0.098 | 0.030 | 24 millimeter | 3.543 | 1.080 | 3 to 3/4″ | 55.780 | 17.001 |

| 5/32″ | 0.095 | 0.029 | 7/8″ | 3.038 | 0.926 | 3 to 1/2″ | 48.772 | 14.850 |

| 5 millimeter | 0.154 | 0.047 | 1″ | 3.970 | 1.210 | 4 to 1/4″ | 72.249 | 21.908 |

| 3/16″ | 0.141 | 0.043 | 25 millimeter | 3.871 | 1.180 | 4″ | 63.340 | 19.306 |

| 6 millimeter | 0.223 | 0.068 | 27 millimeter | 4.490 | 1.368 | 4 to 3/4″ | 90.249 | 27.366 |

| 7/32″ | 0.190 | 0.058 | 26 millimeter | 4.170 | 1.271 | 4 to 1/2″ | 80.340 | 24.4487 |

| 7 millimeter | 0.298 | 0.091 | 30 millimeter | 5.548 | 1.691 | 5 to 1/2″ | 121.000 | 36.690 |

| 1/4″ | 0.249 | 0.076 | 1 to 1/8″ | 5.033 | 1.534 | 5″ | 99.940 | 30.461 |

| 8 millimeter | 0.398 | 0.120 | 32 millimeter | 6.314 | 1.894 | 6 to 1/2″ | 167.630 | 51.093 |

| 5/16″ | 0.387 | 0.118 | 1 to 1/4″ | 6.349 | 1.924 | 6″ | 143.900 | 43.860 |

| 3/8″ | 0.557 | 0.170 | 35 millimeter | 7.553 | 2.390 | 7 to 1/2″ | 225.000 | 68.226 |

| 9 millimeter | 0.498 | 0.152 | 1 to 3/8″ | 7.550 | 2.303 | 7″ | 196.000 | 59.432 |

| 11 millimeter | 0.748 | 0.228 | 38 millimeter | 8.903 | 2.792 | 10″ | 397.140 | 121.048 |

| 10 millimeter | 0.620 | 0.189 | 36 millimeter | 7.999 | 2.438 | 8″ | 254.55 | 77.586 |

| 12 millimeter | 0.889 | 0.271 | 40 millimeter | 9.872 | 3.009 | |||

| 7/16″ | 0.761 | 0.232 | 1 to 1/2″ | 8.951 | 2.715 | |||

| 13 millimeter | 1.043 | 0.318 | 1 to 3/4″ | 12.179 | 3.712 | |||

| 1/2″ | 0.994 | 0.303 | 1 to 5/8″ | 10.449 | 3.200 | |||

| 9/16″ | 1.256 | 0.383 | 1 to 7/8″ | 13.977 | 4.260 | |||

| 14 millimeter | 1.207 | 0.368 | 45 millimeter | 12.555 | 3.807 | |||

| 5/8″ | 1.551 | 0.473 | 50 millimeter | 15.414 | 4.698 | |||

| 15 millimeter | 1.391 | 0.424 | 48 millimeter | 14.205 | 4.330 | |||

| 17 millimeter | 1.791 | 0.543 | 2 to 1/8″ | 17.963 | 5.475 | |||

| 16 millimeter | 1.578 | 0.481 | 2″ | 15.906 | 4.848 | |||

| 18 millimeter | 2.001 | 0.610 | 60 millimeter | 22.205 | 6.768 | |||

| 11/16″ | 1.880 | 0.573 | 2 to 1/4″ | 20.128 | 6.135 | |||

| 3/4″ | 2.237 | 0.682 | 2 to 3/8″ | 22.435 | 6.838 | |||

| 2 to 1/2″ | 24.856 | 7.576 | ||||||

| 2 to 5/8″ | 27.409 | 8.354 | ||||||

| 2 to 3/4″ | 30.083 | 9.169 |

HOW TO GET BEST PRICE OF SS Custom 465 FORGED BAR ?

If looking for Custom 465 Forged Bars and Rod in exact length so first check SS Custom 465 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Chemical Composition Limits | ||||||||||||

| Weight% | Mn | S | Cr | Mo | Ti | Fe | C | P | Si | Ni | Cu | Nb Ta |

| Alloy 465 | 0.50 max | 0.030 max | 11.00 – 12.50 | 0.50 max | 0.80 – 1.40 | Balance | 0.05 max | 0.040 max | 0.50 max | 7.50 – 9.50 | 1.50 – 2.50 | 0.10 – 0.50 |

| Material | Condition | Orientation | 0.2 % Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | % Elongation in 4D | % Reduction of Area | Notch Tensile Strength | NTS/UTS | Charpy V Notch Impact | Rockwell C Hardness |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Long | 1655 | 1765 | 12 | 57 | 2475 | 1.40 | 16 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Trans | 1648 | 1765 | 11 | 49 | 2386 | 1.35 | 13 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Long | 1496 | 1593 | 14 | 63 | 2427 | 1.52 | 35 | 47.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Trans | 1503 | 1600 | 13 | 57 | 2392 | 1.50 | 28 | 47.5 |

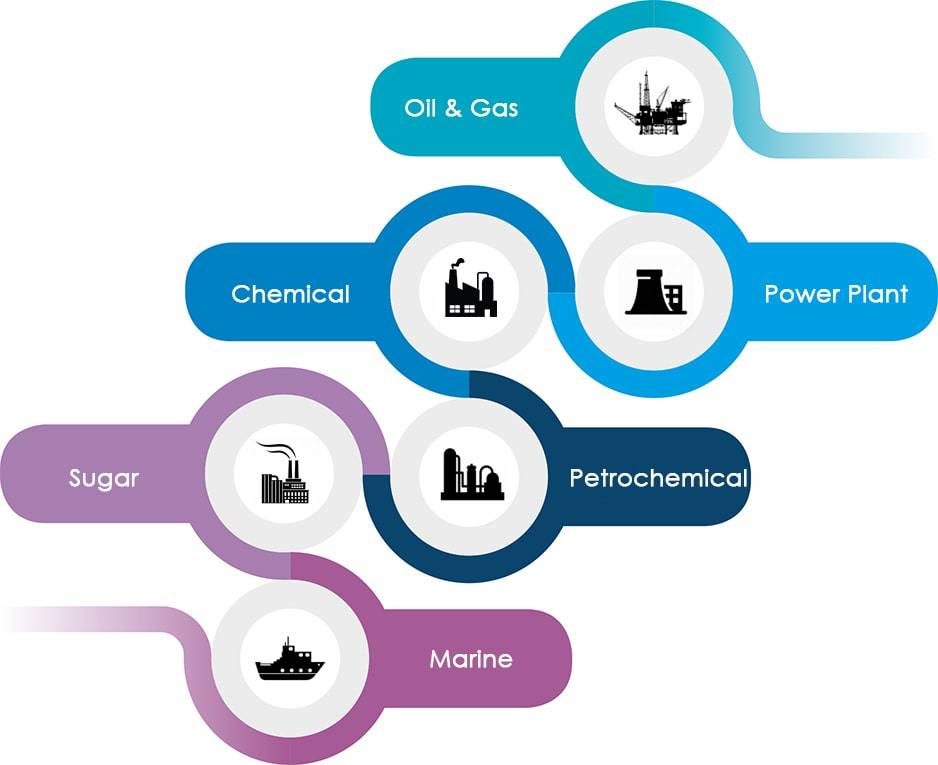

We offer a broad range of ASTM F-899 SS Custom 465 Forged Bars through a worldwide network of stock-keeping branches. These Custom 465 Stainless Steel Forged Rods is use in various industries like :

Qatar, New Zealand, Hungary, Ukraine, Malaysia, United Kingdom, Kuwait, Switzerland, Japan, Italy, Ghana, Mexico, Kenya, China, Oman, Bhutan, Russia, Netherlands, Nigeria, Slovakia, Nigeria, Israel, Chile, Costa Rica, Bahrain, Lithuania, Chile, Serbia, Morocco, Iran, Lebanon, Yemen, Bolivia, Sri Lanka, Mexico, Tunisia, Denmark, Croatia, Saudi Arabia, Singapore, Australia, Jordan, Belarus, Belgium, Argentina, Indonesia, Sweden, Afghanistan, Romania, Estonia, Peru, Austria, Libya, Algeria, Turkey, Spain, South Korea, Finland, Brazil, Mongolia, Vietnam, South Africa, France, Gabon, United Arab Emirates, Iraq, Angola, Colombia, Pakistan, Poland, Azerbaijan, United States, Thailand, Ecuador, Hong Kong, Portugal, Poland, Greece, Kazakhstan, Czech Republic, Trinidad & Tobago, Bulgaria, Norway, Taiwan, Venezuela, Philippines, Bangladesh, Iran, Canada, Egypt.

Nagpur, Visakhapatnam, Jaipur, Ahmedabad, Aberdeen, Jamshedpur, Secunderabad, Abu Dhabi, Granada, Thane, Rio de Janeiro, Rajkot, Howrah, Doha, Jeddah, Edmonton, Ludhiana, Dammam, Kuwait City, Bengaluru, Brisbane, Melbourne, Riyadh, Toronto, Ho Chi Minh City, Noida, New Delhi, Dallas, Chiyoda, Nashik, Algiers, Coimbatore, Ulsan, Baroda, New York, Bogota, Calgary, Ankara, Seoul, Ranchi, Ernakulam, Kanpur, Lagos, Kolkata, Busan, Thiruvananthapuram, Madrid, Pimpri-Chinchwad, Tehran, Surat, Muscat, Milan, Cairo, Ahvaz, Istanbul, Gurgaon, Jakarta, Hyderabad, Haryana, Port-of-Spain, Indore, Chennai, Houston, Atyrau, Bhopal, Pune, Bangkok, Al Jubail, Navi Mumbai, Caracas, Courbevoie, Mumbai, Chandigarh, Manama, Karachi, Faridabad, Vadodara, Sharjah.

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004