Steelo Fabrica is an experienced and reputed fabricator that supplies a wide range Ferralium 255 of Bar and Rods. We offer Rod and Forged Bars manufactured with Ferralium 255 and UNS S32550 materials with standard specifications. Our Forged Bars are widely accepted in heavy industrial use. We offer quality assured Rods in different sizes suitable for applications with required forms and types.

Ferralium 255, duplex stainless steel, is high strength corrosion-proof alloy. It is compiled with 25% of Chromium and Nickel, augmented with Molybdenum and Nitrogen content. The alloy features excellent resistivity against corrosion, pitting, and excellent fatigue strength. Its superior strength to weight quotient proposes its extended application sectors. UNS S32550 is the equivalent grade of Ferralium 255. It is better functioning against chloride and crevice corrosion and ductile. It is widely accepted in corrosive chemicals and acids incorporating sulphuric and nitric acids.

Table of Content

What is Ferralium 255 Forged Bar?

Ferralium 255 Forged Bar is forged with solution annealing to obtain improved structural and impact strength. We produce these bars in different shapes and sizes. These bars are Cost-Effective and easily Formable. Our Forged Bars are excellently stronger and tough structures. They are widely accepted in several corrosive applications due to their excellent resistance. Also, they are wear-resistant and exposed longer to severe conditions.

Ferralium 255 Rod Properties:

Ferralium 255 Rod is a high-quality round-shaped bar with excellent surface protection. It is confined from pitting and crevice rupture. Higher general corrosion resistance improves its surface stability. Also, the Rod is used in chemical surroundings with an efficient deteriorating impediment.

Features of Ferralium UNS S32550 Forged Bar:

These forged bars are used in several applications in square, triangular, rectangle forms. It is easily fabricated and excellently weldable.

Ferralium UNS S32550 Rod is improved with fatigue strength and higher tensile strength. It easily withstands high stress and extreme temperatures. It is widely selected for its excellent strength to weight ratio. These Rods impede aqueous decay and localized attacks.

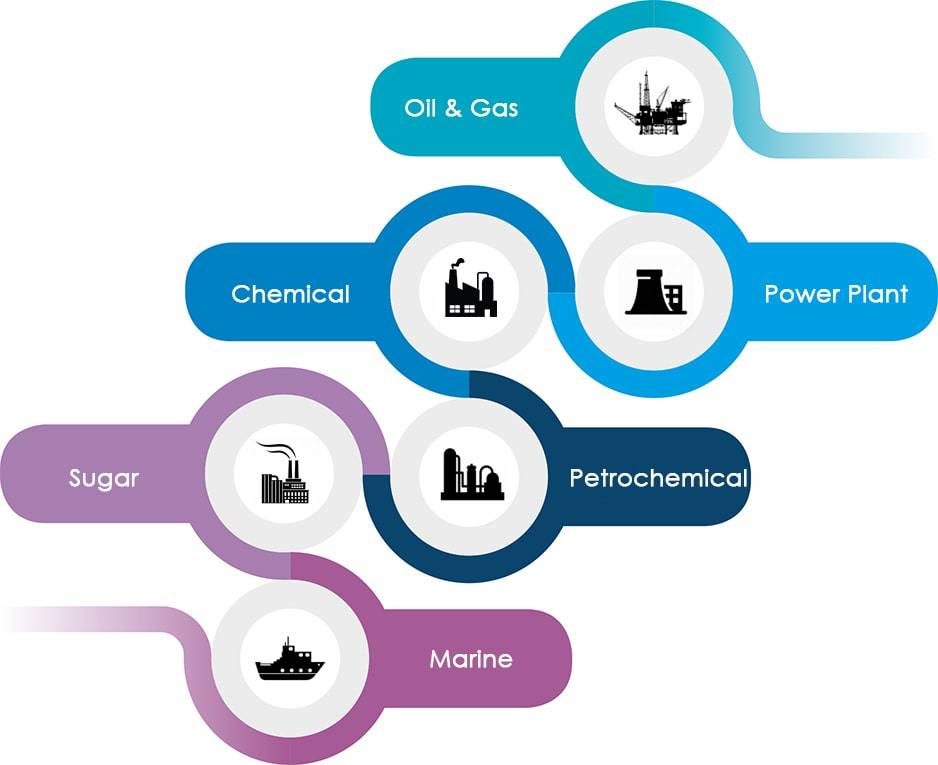

Applications:

Metallurgical, Metalworking Applications

Pollution control, Sanitation, Marine Applications

Chemical, Acid processes, Paper Production

Oil and Gas, Plastics, Petrochemical Industries

Specification : ASTM A276 / ASME SA276

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 1000 MM TO 7000 MM

Outer Diameter : 100MM TO 400 mm Max OD

Weight : 1000 to 6000 Kg

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Tolerance : 0/+2-3mm

| GRADE | STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|---|

| Ferralium 255 | SD50 (Super Duplex 255) | 1.4507 | S32550 |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

|---|---|---|---|---|---|---|---|

| Diameter(Inch) | Size | Diameter (millimeter) | Size | Diameter (millimeter) | Size | Diameter (millimeter2) | Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 0.062 | 0.019 | 22 millimeter | 2.979 | 0.908 | 3 to 1/4″ | 41.996 | 12.800 |

| 3 millimeter | 0.055 | 0.017 | 20 millimeter | 2.470 | 0.753 | 3″ | 35.762 | 10.900 |

| 4 millimeter | 0.098 | 0.030 | 24 millimeter | 3.543 | 1.080 | 3 to 3/4″ | 55.780 | 17.001 |

| 5/32″ | 0.095 | 0.029 | 7/8″ | 3.038 | 0.926 | 3 to 1/2″ | 48.772 | 14.850 |

| 5 millimeter | 0.154 | 0.047 | 1″ | 3.970 | 1.210 | 4 to 1/4″ | 72.249 | 21.908 |

| 3/16″ | 0.141 | 0.043 | 25 millimeter | 3.871 | 1.180 | 4″ | 63.340 | 19.306 |

| 6 millimeter | 0.223 | 0.068 | 27 millimeter | 4.490 | 1.368 | 4 to 3/4″ | 90.249 | 27.366 |

| 7/32″ | 0.190 | 0.058 | 26 millimeter | 4.170 | 1.271 | 4 to 1/2″ | 80.340 | 24.4487 |

| 7 millimeter | 0.298 | 0.091 | 30 millimeter | 5.548 | 1.691 | 5 to 1/2″ | 121.000 | 36.690 |

| 1/4″ | 0.249 | 0.076 | 1 to 1/8″ | 5.033 | 1.534 | 5″ | 99.940 | 30.461 |

| 8 millimeter | 0.398 | 0.120 | 32 millimeter | 6.314 | 1.894 | 6 to 1/2″ | 167.630 | 51.093 |

| 5/16″ | 0.387 | 0.118 | 1 to 1/4″ | 6.349 | 1.924 | 6″ | 143.900 | 43.860 |

| 3/8″ | 0.557 | 0.170 | 35 millimeter | 7.553 | 2.390 | 7 to 1/2″ | 225.000 | 68.226 |

| 9 millimeter | 0.498 | 0.152 | 1 to 3/8″ | 7.550 | 2.303 | 7″ | 196.000 | 59.432 |

| 11 millimeter | 0.748 | 0.228 | 38 millimeter | 8.903 | 2.792 | 10″ | 397.140 | 121.048 |

| 10 millimeter | 0.620 | 0.189 | 36 millimeter | 7.999 | 2.438 | 8″ | 254.55 | 77.586 |

| 12 millimeter | 0.889 | 0.271 | 40 millimeter | 9.872 | 3.009 | |||

| 7/16″ | 0.761 | 0.232 | 1 to 1/2″ | 8.951 | 2.715 | |||

| 13 millimeter | 1.043 | 0.318 | 1 to 3/4″ | 12.179 | 3.712 | |||

| 1/2″ | 0.994 | 0.303 | 1 to 5/8″ | 10.449 | 3.200 | |||

| 9/16″ | 1.256 | 0.383 | 1 to 7/8″ | 13.977 | 4.260 | |||

| 14 millimeter | 1.207 | 0.368 | 45 millimeter | 12.555 | 3.807 | |||

| 5/8″ | 1.551 | 0.473 | 50 millimeter | 15.414 | 4.698 | |||

| 15 millimeter | 1.391 | 0.424 | 48 millimeter | 14.205 | 4.330 | |||

| 17 millimeter | 1.791 | 0.543 | 2 to 1/8″ | 17.963 | 5.475 | |||

| 16 millimeter | 1.578 | 0.481 | 2″ | 15.906 | 4.848 | |||

| 18 millimeter | 2.001 | 0.610 | 60 millimeter | 22.205 | 6.768 | |||

| 11/16″ | 1.880 | 0.573 | 2 to 1/4″ | 20.128 | 6.135 | |||

| 3/4″ | 2.237 | 0.682 | 2 to 3/8″ | 22.435 | 6.838 | |||

| 2 to 1/2″ | 24.856 | 7.576 | ||||||

| 2 to 5/8″ | 27.409 | 8.354 | ||||||

| 2 to 3/4″ | 30.083 | 9.169 |

HOW TO GET BEST PRICE OF SDSS Ferralium 255 FORGED BAR ?

If looking for Ferralium 255 Forged Bars and Rod in exact length so first check SDSS Ferralium 255 price per KG in India and calculate with wight chart before negotiating with your supplier.

| % | Cr | Ni | Mo | Cu | W | C | N | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 24 | 6 | 3 | 0.5 | 0.5 | – | 0.2 | – | – | – | – | – |

| Max | 26 | 8 | 4 | 1 | 1 | 0.03 | 0.3 | 1 | 1 | 0.030 | 0.010 | Balance |

| Grades | Yield Strength (0.2%Offset) | .Tensile Strength | Elongation |

| Ferralium 255 | MPa – 570-600 | MPa – 790 | 25 % |

We offer a broad range of ASTM A276 SDSS Ferralium 255 Forged Bars through a worldwide network of stock-keeping branches. These Ferralium 255 Super Duplex Steel Forged Rods is use in various industries like :

Bhutan, Ecuador, Argentina, Jordan, Tunisia, Hong Kong, Azerbaijan, Israel, Switzerland, Estonia, Portugal, Costa Rica, Colombia, Iran, Netherlands, Sweden, Czech Republic, Belgium, Poland, United States, Lebanon, Bulgaria, Serbia, Vietnam, Japan, United Kingdom, New Zealand, Mexico, Mongolia, Lithuania, Kenya, Hungary, Indonesia, Spain, Kazakhstan, Sri Lanka, Poland, Pakistan, Libya, Afghanistan, Qatar, Yemen, Turkey, Iran, China, Oman, Brazil, Greece, Peru, Gabon, Morocco, Bahrain, Croatia, United Arab Emirates, Finland, South Africa, Nigeria, South Korea, Mexico, Norway, Kuwait, Egypt, Chile, Chile, Angola, Thailand, Venezuela, Belarus, Bolivia, Taiwan, Romania, Iraq, Malaysia, Saudi Arabia, Algeria, Ukraine, Singapore, Trinidad & Tobago, Austria, Slovakia, France, Russia, Canada, Ghana, Denmark, Nigeria, Australia, Italy, Bangladesh, Philippines.

Jeddah, Ludhiana, Caracas, Nagpur, Brisbane, Rio de Janeiro, Surat, Istanbul, Al Jubail, Chandigarh, Thane, Visakhapatnam, Baroda, Aberdeen, Indore, New York, Manama, Muscat, Pimpri-Chinchwad, Haryana, Ulsan, Dallas, Gurgaon, Pune, Calgary, Noida, Bhopal, Atyrau, Algiers, Ankara, Chennai, Melbourne, Bengaluru, Ho Chi Minh City, Milan, Chiyoda, Ranchi, Jaipur, Coimbatore, Tehran, Abu Dhabi, Dammam, Thiruvananthapuram, Faridabad, Kuwait City, Sharjah, Rajkot, New Delhi, Busan, Lagos, Houston, Hyderabad, Howrah, Toronto, Jakarta, Ernakulam, Riyadh, Navi Mumbai, Kanpur, Ahvaz, Granada, Bogota, Bangkok, Nashik, Vadodara, Jamshedpur, Port-of-Spain, Ahmedabad, Karachi, Seoul, Secunderabad, Doha, Cairo, Madrid, Kolkata, Mumbai, Courbevoie, Edmonton.

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004