Steelo Fabrica is a well-known provider and eminent manufacturer of Titanium Grade 2 Flat Bar and ASTM B348 Titanium Grade 2 Flat Bar. We offer a Flat Bar with various standards and specifications, including ASTM B348. Sizes, thicknesses of Bars are defined with different temperature and pressure working conditions. These Bars are broadly commendable in several applications for long life span and serviceability.

Flat Bar made from superb Titanium grade 2 material is a rectangular form of Bar with various thicknesses. The simple structure of the Bar introduces ease of use in structural applications.

Table of Content

Titanium Grade 2 is recognized as a Commercially Pure (CP) Titanium grade with a minimum of 99% of Titanium. Titanium is lightweight and strong with superb corrosion resistance. It is added with a slight impurity of Iron, Oxygen, Carbon, Nitrogen, and Hydrogen. Oxygen improves the strength of the Titanium, and the grade is an excellent corrosion resistant at elevated temperatures. It is a largely utilized grade of Titanium with less alloyed form and is less expensive.

Properties of Titanium Grade 2 alloy:

• Superior strength to weight ratio

• Commendable tensile strength

• Very high Melting Point

• More ductile and efficiently weldable

• Suitable in corrosive surroundings

• Elevated heat creep protection

ASTM B348 Titanium Grade 2 Flat Bar is fabricated with specification ASTM B348 that covers annealed Bars made of Titanium and Titanium alloys. Thus these Flat Bars are often recommended in aggressive media with outstanding corrosion resistance. These are provided in annealed condition that improves the physical properties of Flat Bars. Also, they are enhanced with excellent ductility and greater workability.

Titanium Grade 2 Flat Bar is lightweight with excessive strength and, therefore, more suitable in heavy applications. These Bars are efficiently workable in harsh corrosive media. It resists decomposition in atmospheric, high temperature, and marine surroundings. It is protected from creep and crevice impact and reduces rupture prospects. These Bars are widely utilized in aerospace structures and withstand extreme temperatures. Corrosive surroundings in oil and chemical processing are resisted to decompose the Bars. They are extremely tensile and distress in extreme pressure and intense heat corrosion.

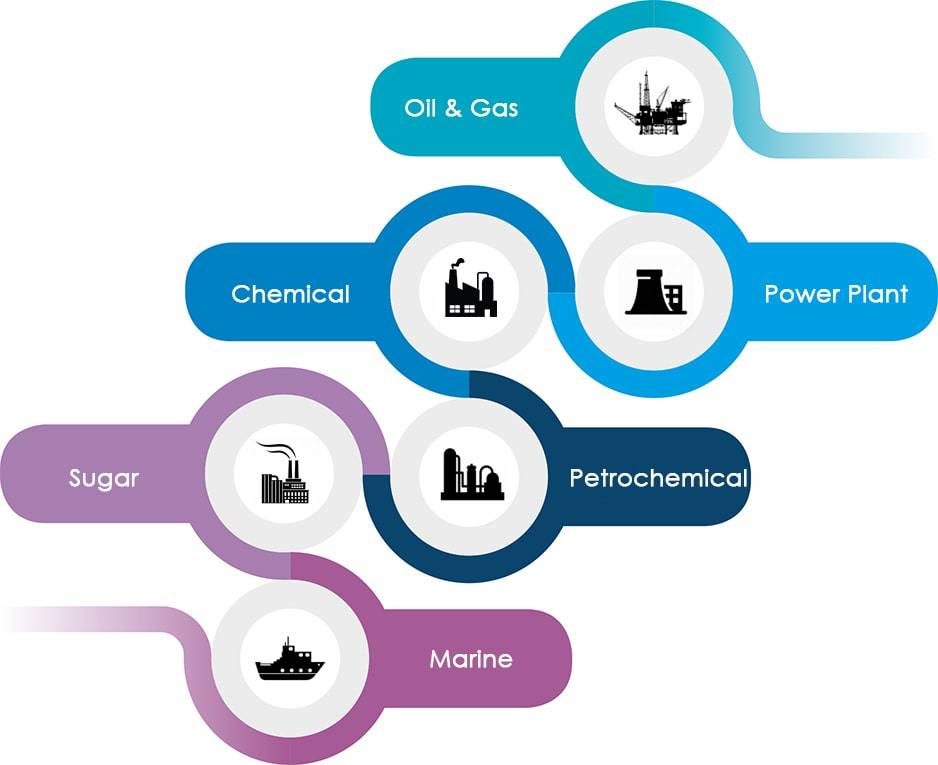

Applications of Titanium Grade 2 Flat Bar

• Oil and Gas

• Aerospace

• Medical Equipment

• Flue Gas Desulphurization

• Naval

• Chemical

ASTM B348

ASME SA-348

UNS R50400

WNR. 3.7035

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr 2 | 3.7035 | R50400 |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| Size(mm) | 6 mm | 8 mm | 10 mm | 12 mm | 16 mm | 18 mm | 20 mm | 25 mm | 30 mm | 32 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1.20 | 1.60 | 2.00 | 2.40 | — | — | — | — | — | — |

| 30 | 1.44 | 1.92 | 2.40 | 2.88 | — | — | — | — | — | — |

| 32 | 1.54 | 2.05 | 2.56 | 3.07 | — | — | — | — | — | — |

| 35 | 1.68 | 2.24 | 2.80 | 3.36 | — | — | — | — | — | — |

| 38 | 1.82 | 2.24 | 3.04 | 3.65 | 4.86 | 5.47 | 6.08 | — | — | — |

| 40 | 1.92 | 2.56 | 3.20 | 3.84 | 5.12 | 5.76 | 6.40 | — | — | — |

| 45 | 2.16 | 2.88 | 3.60 | 4.32 | 5.76 | 6.48 | 7.20 | — | — | — |

| 50 | 2.40 | 3.20 | 4.00 | 4.80 | 6.40 | 7.20 | 8.00 | 10.00 | 12.00 | 12.80 |

| 55 | 2.64 | 3.52 | 4.40 | 5.28 | 7.04 | 7.92 | 8.80 | 11.00 | 13.20 | 14.08 |

| 60 | 2.88 | 3.84 | 4.80 | 5.76 | 7.68 | 8.64 | 9.60 | 12.00 | 14.40 | 15.36 |

| 63 | 3.02 | 4.03 | 5.04 | 6.05 | 8.06 | 9.07 | 10.08 | 12.60 | 15.12 | 16.13 |

| 65 | 3.12 | 4.16 | 5.20 | 6.24 | 8.32 | 9.36 | 10.40 | 13.00 | 15.60 | 16.64 |

| 70 | 3.36 | 4.48 | 5.60 | 6.72 | 8.96 | 10.08 | 11.20 | 14.00 | 16.80 | 17.92 |

| 75 | 3.60 | 4.80 | 6.00 | 7.20 | 9.60 | 10.80 | 12.00 | 15.00 | 18.00 | 19.20 |

| 80 | 3.84 | 5.12 | 6.40 | 7.68 | 10.24 | 11.52 | 12.80 | 16.00 | 19.20 | 20.48 |

| 90 | 4.32 | 5.76 | 7.20 | 8.64 | 11.52 | 12.96 | 14.40 | 18.00 | 21.60 | 25.04 |

| 100 | 4.80 | 6.40 | 8.00 | 9.60 | 12.80 | 14.40 | 16.00 | 20.00 | 24.60 | 25.60 |

| Size(mm) | WT PER FEET IN KGS | WT PER MTR IN KGS |

|---|---|---|

| 16 | 0.62 | 2.05 |

| 18 | 0.79 | 2.59 |

| 20 | 0.76 | 2.49 |

| 22 | 1.18 | 3.87 |

| 25 | 1.52 | 5.00 |

| 28 | 1.91 | 6.27 |

| 30 | 2.19 | 7.20 |

| 32 | 2.50 | 8.19 |

| 36 | 3.16 | 10.37 |

| 38 | 3.52 | 11.55 |

| 40 | 3.90 | 12.80 |

| 45 | 4.94 | 16.20 |

| 50 | 6.10 | 20.00 |

| 56 | 7.65 | 25.08 |

| 60 | – | – |

| 65 | – | – |

| 70 | – | – |

| 75 | – | – |

| 80 | – | – |

| 90 | – | – |

| 100 | – | – |

HOW TO GET BEST PRICE OF TITANIUM GRADE 2 FLAT BAR ?

If looking for Flat Bar in exact length so first check Titanium Grade 2 price per KG in India and calculate with wight chart before negotiating with your supplier.

| Grade | C | N | O | H | Ti | Fe |

| Titanium Gr 2 | 0.10 max | 0.03 max | 0.25 max | 0.015 max | bal | 0.30 max |

| Min.Tensile(KSI) | Min.Yield(KSI) | Hardness | Tensile Modulus | Poisson’s Ratio |

| 50 | 40 | 14.9 | 103 GPa | 0.34 – 0.10 |

Products

27 2nd Floor Rangwala Building, N D Road, 58, Islampura Street, Cawasji Patel Tank, Bhuleshwar, Mumbai, Maharashtra 400004